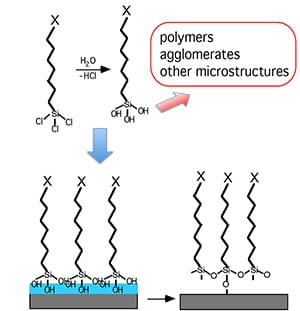

Since its introduction by Sagiv over three decades ago [J. Am. Chem. Soc., 1980, 102, 92-98], the formation of silane monolayers has been developed into a versatile tool for controlling surface chemical and physical properties. The physical and chemical properties of a solid surface are largely determined by those of the outmost layer of atoms or chemical groups. As a result, coating the surface with a monolayer allows us to easily tune the desired properties, such as hydrophobic, hydrophilic, specific reactivity towards a particular functional group, positive or negative charge under physiological conditions, etc. The basic principle for silane monolayer formation is illustrated in Figure 1. The starting molecule for functionalization usually consists of three parts: the reactive silane group (trichloro, trimethoxy, or triethoxy) for attachment to the solid surface, an alkyl spacer, and an end group (X) for the functionality of interest. In the presence of a trace amount o f water in the solvent, the silane groups hydrolyze into silanols (Si-OH) and assemble on a hydrophilic surface. Subsequent cross-linking among the silanol groups and attachment to the surface results in a robust monolayer, with the functional group of interest, X, exposed on the top most surface.

f water in the solvent, the silane groups hydrolyze into silanols (Si-OH) and assemble on a hydrophilic surface. Subsequent cross-linking among the silanol groups and attachment to the surface results in a robust monolayer, with the functional group of interest, X, exposed on the top most surface.

The process of forming a silane monolayer simply involves dipping a solid surface in a solution of the silane molecule of interest in a suitable solvent (e.g., toluene) for a fixed time and then rinsing the surface with the solvent. This procedure is deceivingly simple and most users have attempted this procedure in house. However, the success rate of obtaining high quality silane coatings is not particularly high. The problem lies in the exceptional sensitivity of the silane coating chemistry to experimental conditions, such as the solvent, humidity of the ambient air, the concentration of the trace amount of water in the solvent, surface cleaning, and temperature, etc. Competitive reactions can easily lead to polymer and aggregate formation due to cross linking in the solution phase. As a result, the quality of the silane coating varies greatly from lab to lab and from person to person.

For over a decade, we have carefully studied and optimized the fabrication of silane monolayers on a variety of material surfaces. We have turned the “black magic” into a consistent, reproducible, and quality controlled technology. We now make our expertise available to you by offering a broad range of functional silane coating at customer specifications. These coatings are available on standard microscope slides, coverslips, silicon wafers. We also provide customer coating service for specific customer samples. Our customers have successfully applied various silane coatings for a broad range of applications. Talk to our scientists about your needs and we will help you achieve your R&D goals.

Copyright © 2015 Athena Guo. All rights reserved.