FEATURES :

Features to Consider when Shopping for a High Speed Shaking Bead-mill Cell Disrupter…

SHAKING TIME: If you are harvesting intercellular proteins you will want close to 100% cell disruption. The MiniBeadbeater series of cell disrupters deliver those high yields with 2-3 minutes of beadbeating. Some high-speed bead mill manufacturers claim “disruption times” of less than 30 seconds. That shorter time may suffice for PCR work where a partial extraction of nucleic acids is adequate, but for blotting methods or protein recovery, higher yields require more beadbeating time.

SHAKING SPEED: Some commercial bead-mill cell disrupters express their disruption setting as meters/second (m/s). This term combines shaking speeds in rpm with vial displacement distance to create a unit that supposedly defines a bead-mill’s cell disruption power to mechanically lyse cells. The fact is that there is no available formula that comprehensively defines cell disruption efficiency of bead mill grinding machines. Were a term to exist, it would need to take into consideration not only shaking speed and distance of vial displacement but additional important variables such as shaking direction (vertical vs.horizontal), shaking pattern (linear vs.figure eight), kinetics of change in shaking direction (sigmoidal vs. square wave), vials used (size and shape) and beads used (sizes, composition, bead load).

VIAL ORIENTATION, SHAKING PATTERN and SHAKING DISTANCE (THROW): Most bead mill cell disrupters shake 2 ml microvials in either a vertical (upright) or approximately horizontal direction. In terms of cell disruption efficiency (CDE), the horizontal position is more efficient than vertical. All shaking-type beadbeaters have flattened figure-eight shaking patterns. The exact shape of this figure-eight pattern has little impact on the CDE. Shaking distance (throw), however, has a significant impact on CDE. By necessity, all shaking type bead mill cell disrupters must have a vial throw of about ¾ to 1 inch.

The interplay of these multiple variables is complex. Each manufacturer attempts to optimize the interaction of these variables when designing their cell disrupter machine. As might be expected, some machines have achieved this goal better than others.

A final point: Published cell lysis protocols using high-speed bead-mill cell disrupters are seldom operated at shaking speeds less than the maximum speed. Thus, the availability of variable speed settings, be they “rpm” or “M/s”, might be viewed as a ‘bell and whistle’ feature.

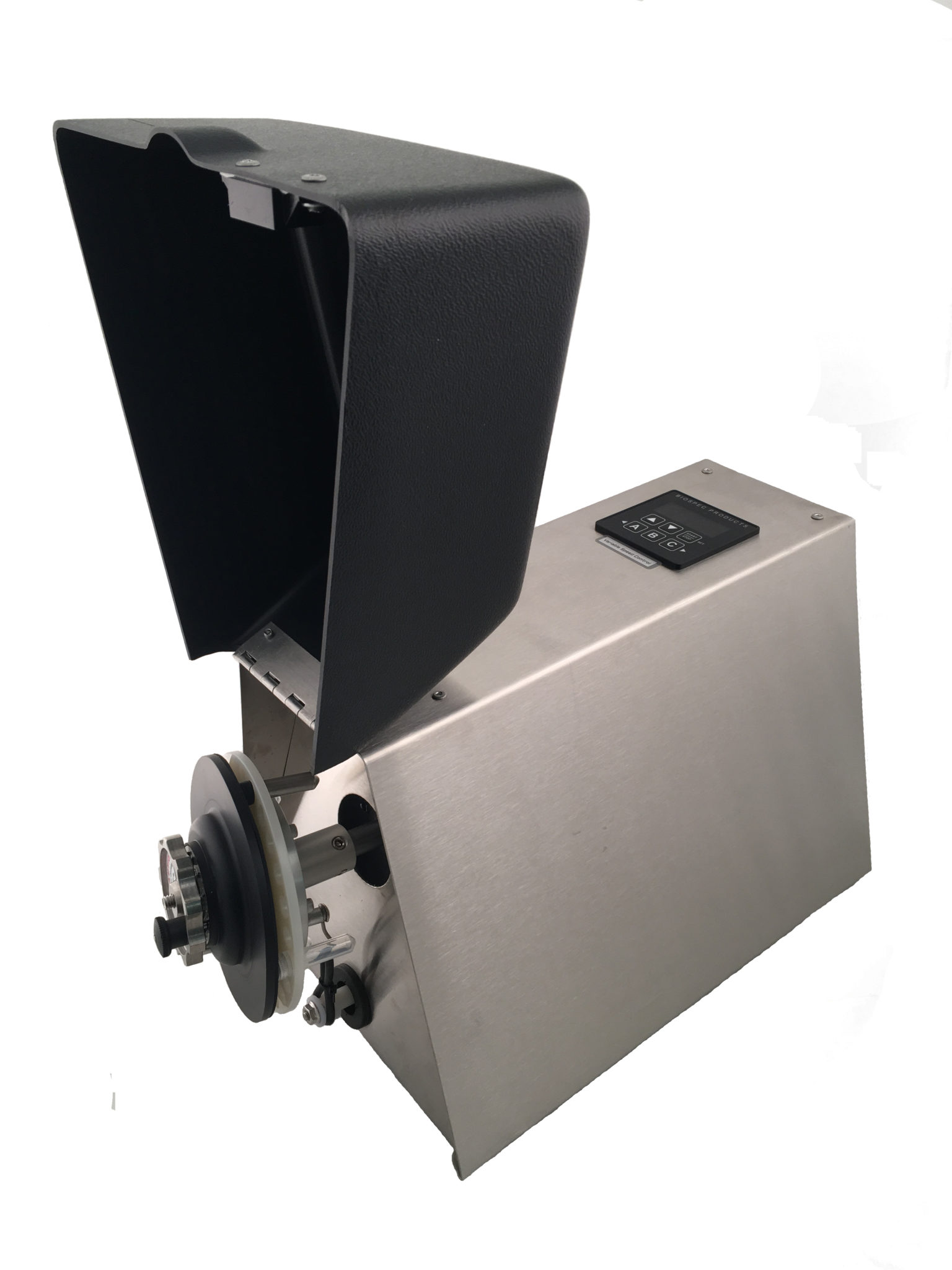

SPECIFICATIONS :

- Power: 115 volts, 60 Hz, 7.4 amp or 230 volts, 50 Hz, 3.7 amps.

- Width 10 in, Depth 16 in, Height 12 in, Weight 40 pounds.

- Shaking pattern: Uses proven, more efficient near horizontal vial orientation with shaking motionand a “figure 8” shaking pattern.

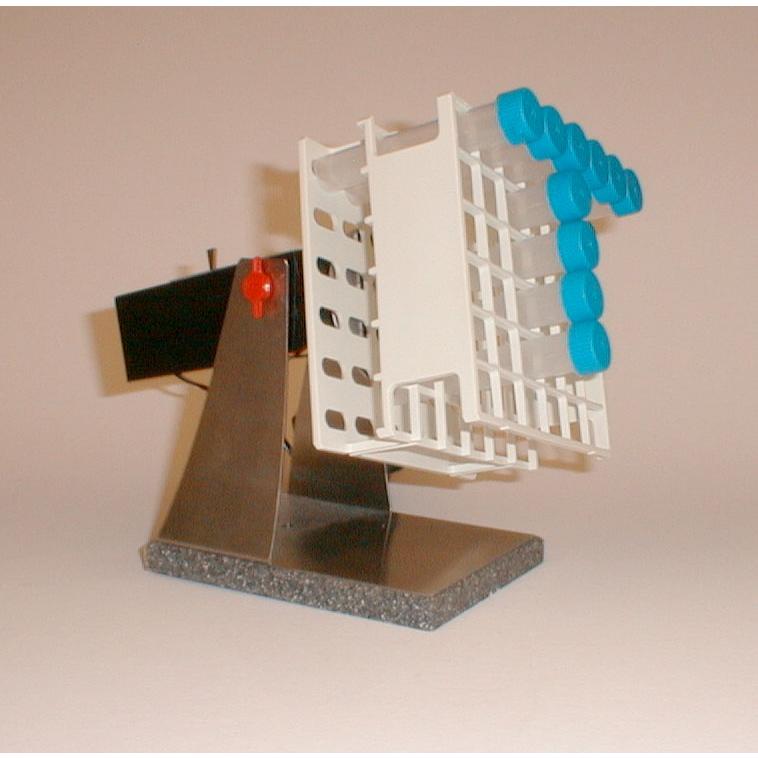

- Capacity: Four to sixteen screw-cap microvials (0.5, 1.5 and 2.0 ml) with each handling up to 400 mg (wet weight) bio-sample.

- Shaking speed: 3450 oscillations/min. The CDE “performance” meets or exceeds all other bead-mill cell disrupters on the market (see detais below).

- Throw or vial displacement: 0.75 inches.

- Timer: 0-5 minute digital, with auto reset.

- Removable vial-holding cassette.

- No required motor cool-down-time between sample runs.

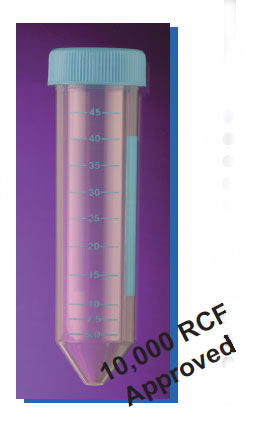

The MiniBeadBeater-16 uses standard screw-cap plastic microvials. Stainless steel microvials or a specially reinforced polypropylene microvial (XXTuff vials) are available when dry- or cryo-milling with steel beads. Larger 7 ml vials can be processed with an accessory holding ring.

Confusing Specifications – information for first-time buyers…

SHAKING TIME: If you are harvesting intercellular proteins you will want close to 100% cell disruption. The MiniBeadbeater series of cell disrupters deliver those high yields with 2-3 minutes of beadbeating. Some high-speed bead mill manufacturers claim “disruption times” of less than 30 seconds. That shorter time may suffice for PCR work where a partial extraction of nucleic acids is adequate, but for blotting methods or protein recovery, higher yields require more beadbeating time.

SHAKING SPEED: Some commercial bead-mill cell disrupters express their disruption setting as meters/second (m/s). This term combines shaking speeds in rpm with vial displacement distance to create a unit proposed to define a bead-mill cell disruption power to mechanically lyse cells. The fact is that there is no available formula that comprehensively defines the cell disruption efficiency of bead mill grinding machines. Were a term to exist, it would need to take into consideration not only shaking speed and distance of vial displacement but additional important variables such as shaking direction (vertical vs.horizontal), shaking pattern (linear vs.figure eight), kinetics of change in shaking direction (sigmoidal vs. square wave), vials used (size and shape) and beads used (sizes, composition, bead load).

VIAL ORIENTATION, SHAKING PATTERN and SHAKING DISTANCE (THROW): Most bead mill cell disrupters shake 2 ml microvials in either a vertical (upright) or approximately horizontal direction. In terms of cell disruption efficiency (CDE), the horizontal position is more efficient than vertical. All shaking-type beadbeaters have flattened figure-eight shaking patterns. The exact shape of this figure-eight pattern has little impact on the CDE. Shaking distance (throw), however, has a significant impact on CDE. By necessity, all shaking type bead mill cell disrupters must have a vial throw of about ¾ to 1 inch.

The interplay of these multiple variables is complex. Each manufacturer attempts to optimize the interaction of these variables when designing their cell disrupter machine. As might be expected, some machines have achieved this goal better than others.

A final point: Published cell lysis protocols using high-speed bead-mill cell disrupters are seldom operated at shaking speeds less than the maximum speed. Thus, the availability of variable speed settings, be they “rpm” or “M/s”, might be viewed as a ‘bell and whistle’ feature.

OTHER INFO :

…..from a Researcher at Lawrence Livermore National Lab: ‘We have now tested the MiniBeadBeater-16 with two different sets of samples, with more than 100 samples processed. It seems to perform comparably with the single channel units we have from BioSpec, which is a very pleasant surprise. We are able to isolate DNA from purified Bacillus spores, which have proved to be too difficult for all of the other commercially available, multi-channel instruments we have tried.’ {*Not to be taken as an endorsement by LLNL or its affiliates}

…..from Ontario Veterinary College: ‘We received your MiniBeadbeater and put it to use immediately. It is just as advertised, easy to use, and our tissue homogenization and resultant RNA isolation has improved drastically!!’

Great prices

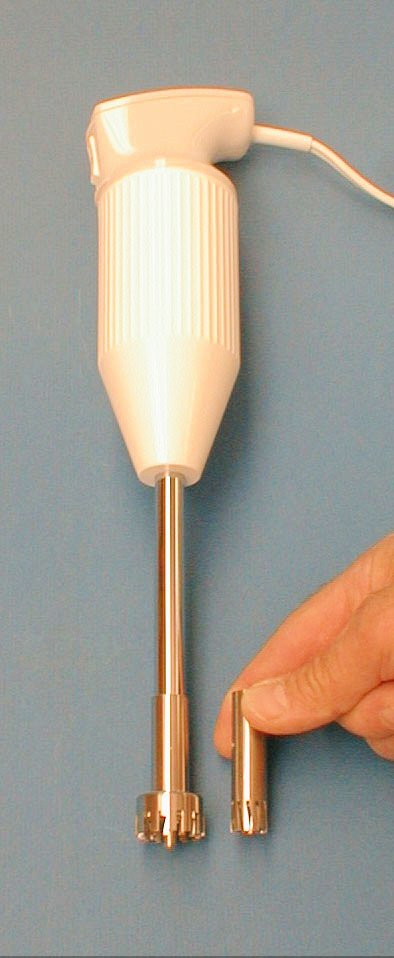

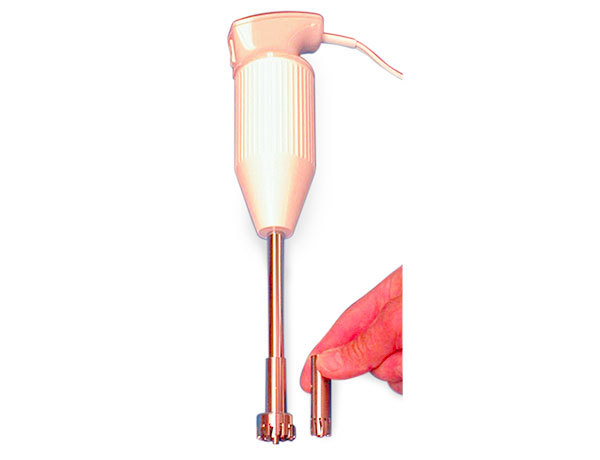

…..from Steve @emu.edu: ‘I’m shopping around for a bead-beater kind of homogenizer, and the Mini-Beadbeater-16 looks great, price-wise anyway, compared to the Fastprep™ and other similar products. How does it compare to the other $7000-$10000 bead beaters on the market and why is it so much cheaper?’ Answer: For over 30 years our business model has been to offer quality scientific equipment at reasonable prices. BioSpec accomplishes this in two ways: 1. Sometimes we design and build equipment which incorporates a preexisting mass-marketed tools or appliances (example: our ‘TissueTearor’ homogenizer uses a low cost Dremel-tool motor drive). Savings from this strategy are passed on to the customer. 2. We advertise modestly. Advertising costs associated with print and digital advertising, distributor and customer discounts, representative commissions, and trade shows must be factored into a final product price…indeed, offsetting promotional costs can account for 50% of the sales price of a lab tool.

What is meter/second?

…..from Alexa at Mt Sinai School of Medicine: ‘I received a protocol from another lab where they used a FastPrep™ machine to lyse Staphylococcus aureus for RNA isolation. I wanted to use a BioSpec bead beater in my lab for cell disruption. The FastPrep protocol called for 20 seconds at a setting 4.0 m/s, cool on ice for 5 minutes, then process again for 20 seconds at a setting of 4.5 m/s. You suggested that I try a total of 30 seconds in the MiniBeadbeaater, alternating between 10 seconds beadbeating and 1 minute cooling in ice-water. I am writing to let you know that this revised protocol is working for me. If anyone else is having a similar problem, please feel free to have them contact me’. …And a related question from Teresa, Virginia Tech: ‘I have a protocol that uses the FastPrep at a machine setting of 6.5 m/s. What does the FastPrep setting mean and what is the cell disruption speed I should use with my new MiniBeadbeater?’ Answer: In our opinion, the original manufacturer of FastPrep machines did not do the scientific community a service by coming up with the term ‘m/sec’ to express cell breakage performance. The term, which lumps shaking speed and vial displacement into a single “physical unit”, does not and can not comprehensively describe cell disruption efficiency of a bead mill.

Such a term, were it to exist, would have to take into consideration not only shaking speed and distance of vial travel (throw), but also the shaking direction (vertical/horizontal), shaking pattern (linear/figure eight), kinetics of change in shaking direction (sigmoidal/square wave), vial size and shape and other variables. Clearly, the interplay of these variables is complex and poorly defined. In designing an efficient bead mill to disrupt cells engineers must take into consideration all of these variables and, as might be expected, some commercial machines achieve this goal better than others.

Here is a Rule of Thumb for operating any bead mill cell disruption machine offering variable shaking speed, whether made by BioSpec or another manufacturer: If the objective is to disrupt cells operate the machine at its maximum speed setting. Special applications requiring lower operating speeds are rare.

Grinding time will vary, depending on the type of sample. Generally, 2-3 minutes will get you close to total cell lysis. If you are doing PCR work and can settle for less than total cell lysis, shorter periods of beadbeating may suffice. Also important for good cell disruption is the choice of bead size, bead composition, and bead load. These details are covered in operating instructions that accompany our machines or contact us technical@stratech.co.uk